Vane components

Carbon Vanes

Applications

The applications where carbon vanes are being used are extensive. Typical of these

are: The applications where carbon vanes are being used are extensive. Typical of these

are:

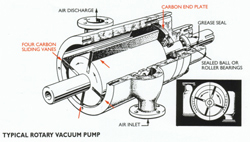

- Dry running rotary compressors and vacuum pumps

- Mobile compressors fitted to bulk delivery tankers

- printing machinery

- Spray paint equipment

- Packing machinery

- Food processing equipment

- Wet running vane pump and meters

- Automotive diesel fuel pumps

- Drink vending machines

- Fuel tanker meters

Morgan Industrial Carbon vanes are made in a range of carbon materials (carbon graphite, metal impregnated carbon graphite and resin bonded graphite) to meet many differing application requirements. All Morgan Industrial carbon grades retain the basic properties which make carbon unique as an engineering material, and particularly suited for vanes which may operate in conditions beyond the limits of other materials.

Carbon vanes are self lubricating, and therefore ideal for pumps handling liquids whose lubricating properties are poor, such as petrol. They can also operate unlubricated in compressors to deliver air or gas uncontaminated by lubricated oil or grease, in which the carbon gives a fine polish to the cylinder wall which reduced the wear rate of the vane after bedding in to negligible proportions.

Carbon vanes are chemically inert , non-toxic and cannot contaminate the liquid or gas being handled. They can safely be used in food processing equipment and in other fields where purity is essential.

Carbon vanes are totally unaffected by water, most acids, alkalies or oil solvents such as petrol or paraffin. In these conditions, the liquid can reduce friction and wear by providing lubrication between vane and rotor slots and vane top and cylinder wall.

One of the most important requirements for vane materials is high mechanical strength. Carbon vanes meet this requirement. Their strength is indicated by the pressures regularly handled which range from 3.2 Kgf/cm2 (454 lbf/in2) down to high vacuum conditions, with peripheral speeds up to 12.7 m/sec (2500 ft/min)

What We need

To assist Morgan Industrial Carbon in the manufacture of your vanes, please furnish us with the relevant

information:

- Vane quantity required

- Width of vane

- Depth of vane

- Thickness of vane

- Material being pumped

Please contact

us, outlining your specific requirements.

|